Khoom

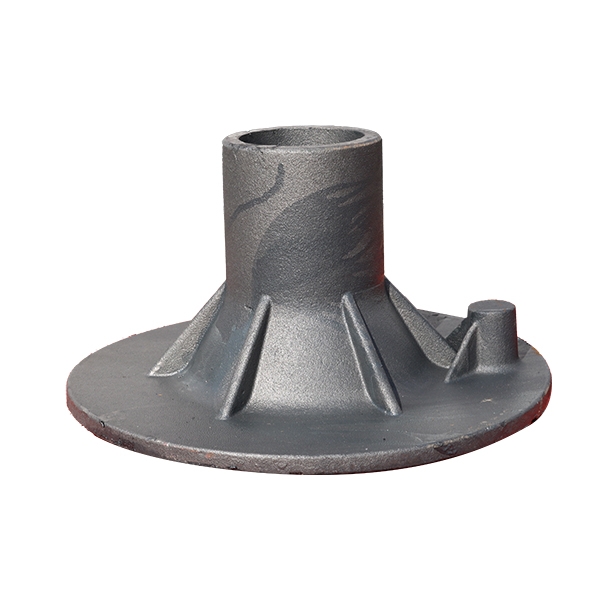

AZ2220000201 Pem Hauv Ntej Qag Khaub Ncaws

Khoom Feature

Poob npam casting (tseem hu ua puab yas ua npuas dej rau hauv cov qauv ua npuas ncauj thiab cov kab mob STMMA lossis EPMER) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) Nrog refractory txheej (muaj zog), du thiab qhuav) thiab qhuav, nws tau faus rau hauv cov xuab zeb qhuav qhuav ua qauv. Lub molten hlau tau nchuav rau hauv cov moulding xuab zeb hauv lub siab tsis zoo, yog li cov qauv polymer yog rhuab thiab muab rho tawm. Ib txoj kev tshiab casting uas siv cov hlau ua kua los hloov ib-zaug pwm ua kom haum cov txheej txheem tom qab txias thiab solidification los tsim cov casings. Poob ua npuas dej casting muaj cov yam ntxwv hauv qab no: 1. Cov khoom siv tau zoo thiab tus nqi qis; 2. Cov ntaub ntawv tsis txwv thiab haum rau txhua qhov ntau thiab tsawg; 3. Lub siab ntsuas, du nto, tsis tu dua, thiab tsawg dua machining; 4. Sab saum toj tsis xws luag yog zoo heev txo thiab cov qauv ntawm cov nrib yog txhim kho. Ntom; 5. Nws tuaj yeem paub cov nplai loj thiab ntau lawm; 6. Nws yog haum rau huab hwm coj ntau lawm Casting ntawm tib cov kab hlau; 7. Nws yog haum rau kev ua haujlwm ntawm kev ua haujlwm thiab cov kab sib dhos ua ke tsim thiab tswj kev ua haujlwm; 8. Cov kab haujlwm ntau lawm ntawm cov kab ntau lawm tau raws li qhov yuav tsum tau muaj kev tiv thaiv ib puag ncig kev tiv thaiv. ; 9. Nws tuaj yeem txhim kho kev ua haujlwm ib puag ncig thiab cov xwm txheej ntau lawm ntawm cov kab ntau lawm, txo kev siv zog ua haujlwm, thiab txo kev siv zog.

Khoom Piav Qhia

Tus qauv tsim tau hloov tau thiab muab kev ywj pheej txaus rau kev tsim qauv nrum ua qauv. Cov khoom siv ua kom pom tseeb tuaj yeem raug pov los ntawm kev sib xyaw ua ke pwm.

Txo cov peev txheej kev nqis peev thiab cov nqi ntau lawm, txo qhov hnyav ntawm cov ntawv tsis zoo, thiab muaj cov khoom siv me me. (1) batch kom muaj nuj nqis ntawm cov casings (2) casting khoom (3) casting loj (4) Casting qauv

Tsis muaj cov xuab zeb tseem ceeb hauv kev ua yeeb yam, yog li yuav tsis muaj qhov tsis ncaj ntawm cov cuab yeej ua tuab ntawm cov cuab yeej xuab zeb loj lossis cov tub ntxhais qub tsis raug.

.Asts muaj qhov ntsuas siab. Poob npuaj teg casting yog ib qho txheej txheem tshiab nrog kev tsis muaj npoo thiab pwm kom raug. Tus txheej txheem no tsis tas yuav tau pwm, thiab tsis muaj cov xuab zeb tseem ceeb, yog li cov ntawv yuam kev tsis muaj qhov yuam kev, thiab kev sib xyaw ua ke los ntawm kev sib xyaw ua ke yog txo. Qhov saum npoo roughness ntawm cov duab cas tuaj yeem ncav cuag ra3.2 txog 12,5μm; Qhov tseeb ntawm qhov tseeb ntawm cov duab cas tuaj yeem ncav cuag CT7 txog 9; Cov tshuab them nyiaj yog 1.5 txog 2 hli ntawm feem ntau, uas tuaj yeem txo tus nqi ntawm machining. Piv nrog cov tsoos xuab zeb casting txheej txheem, nws tuaj yeem txo los ntawm 40% rau 50% ntawm machining sijhawm.

Ntau lawm, tsis muaj tshuaj lom neeg nyob rau hauv cov moulding xuab zeb, ua npuas ncauj yog ib puag ncig ntawm qhov kub thiab txias ntawm cov qub xuab zeb tau tshaj li 95%.

Xav tham txog yam uas peb tuaj yeem ua tau rau koj?

Tshawb nrhiav qhov twg peb cov kev daws teeb meem tuaj yeem coj koj.