Khoom

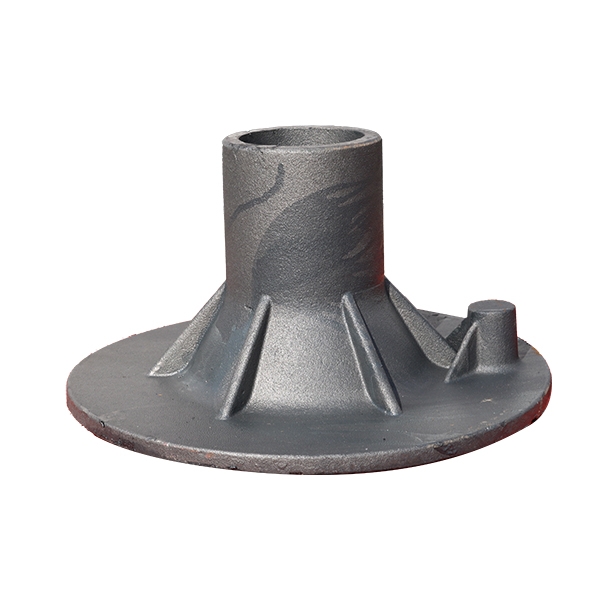

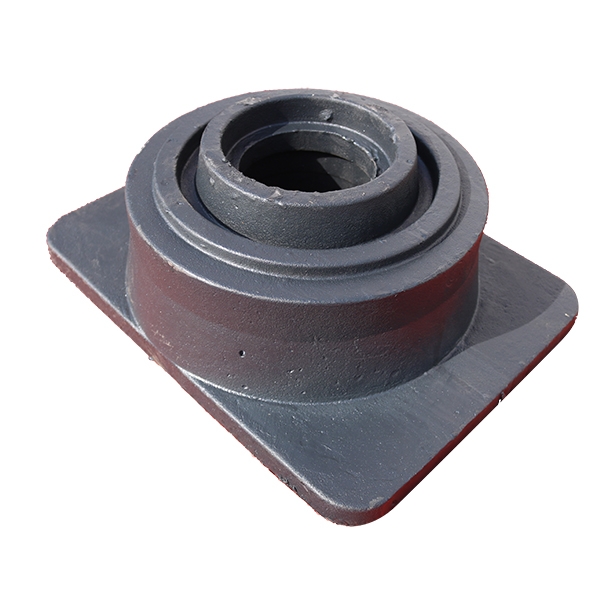

GVT1501020055 HUB REDUCER

Khoom Feature

Poob npam casting (tseem hu ua puab yas ua npuas dej rau hauv cov qauv ua npuas ncauj thiab cov kab mob STMMA lossis EPMER) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) Nrog refractory txheej (muaj zog), du thiab qhuav) thiab qhuav, nws tau faus rau hauv cov xuab zeb qhuav qhuav ua qauv. Lub molten hlau tau nchuav rau hauv cov moulding xuab zeb hauv lub siab tsis zoo, yog li cov qauv polymer yog rhuab thiab muab rho tawm. Ib txoj kev tshiab casting uas siv cov hlau ua kua los hloov ib-zaug pwm ua kom haum cov txheej txheem tom qab txias thiab solidification los tsim cov casings. Poob ua npuas dej casting muaj cov yam ntxwv hauv qab no: 1. Cov khoom siv tau zoo thiab tus nqi qis; 2. Cov ntaub ntawv tsis txwv thiab haum rau txhua qhov ntau thiab tsawg; 3. Lub siab ntsuas, du nto, tsis tu dua, thiab tsawg dua machining; 4. Sab saum toj tsis xws luag yog zoo heev txo thiab cov qauv ntawm cov nrib yog txhim kho. Ntom; 5. Nws tuaj yeem paub cov nplai loj thiab ntau lawm; 6. Nws yog haum rau huab hwm coj ntau lawm Casting ntawm tib cov kab hlau; 7. Nws yog haum rau kev ua haujlwm ntawm kev ua haujlwm thiab cov kab sib dhos ua ke tsim thiab tswj kev ua haujlwm; 8. Cov kab haujlwm ntau lawm ntawm cov kab ntau lawm tau raws li qhov yuav tsum tau muaj kev tiv thaiv ib puag ncig kev tiv thaiv. ; 9. Nws tuaj yeem txhim kho kev ua haujlwm ib puag ncig thiab cov xwm txheej ntau lawm ntawm cov kab ntau lawm, txo kev siv zog ua haujlwm, thiab txo kev siv zog.

Khoom Piav Qhia

1. Lub tshuab nqus tsev qis poob ua npuas ua npuas ntxau tshuab. Nws muab cov txiaj ntsig zoo ntawm cov khoom siv hluav taws xob qis thiab nqus cov txheej txheem ua npuas dej, ua tiav cov txheej txheem ua tiav nyob rau hauv cov pa hluav taws xob puv ntawm cov alloy. Piv nrog tuag casting, cov cuab yeej siv peev yog me me, tus nqi yog tsawg, thiab cov kab tsuag tuaj yeem txhawb nqa los ntawm kev kho cua sov; Piv nrog xuab zeb casting, cov castings muaj qhov siab precision, cov khoom siv roughness qis, kev tsim khoom zoo, thiab ua tau zoo. Raws li kev nqis tes ua ntawm kev tawm tsam, lub Sprue ua rau cov channel shortening, thiab poob ntawm nchuav kub yog me me. Lub pouring system ntawm alloy caso casts yog yooj yim thiab siv tau zoo, nrog siab tawm los thiab cov qauv tuab. Qhov yuav tsum tau ncuav kub yog qhov tsawg thiab yog haum rau pouring thiab sib sau ntawm ntau cov tsis muaj alloys. Cov.

2. Inception liam poob ua npuas ncauj tshuab. Nws muab cov khoom siv ua npuas xab castting thev naus laus zis nrog lub siab ua kom lub siab siv tshuab. Nws lub hauv paus ntsiab lus yog nchuav rau hauv cov hlau ua rau hauv lub taub hau tank nrog lub thawv xuab zeb kom ua kom cov pwm ua npuas dej kom ua kom cov roj av tank thiab qhia cov roj ntawm ib qho siab. , ua rau cov hlau molten rau solorify thiab crystallize nyob rau hauv siab. Cov yam ntxwv ntawm cov thev naus laus zis yog tias nws tuaj yeem txo cov cam xeeb casting xws li shrinkage castings, thiab txhim kho cov khoom siv tshuab ntawm cov cuab yeej cuab tam ntawm castings. Kev ruaj khov nyob rau hauv sab nraud siab tuaj yeem ua rau lub tshuab hluav taws xob ntawm lub sijhawm pib ua kom muaj peev xwm thiab txhim kho kev phom sij sab hauv ntawm lub casting. Nyob rau tib lub sijhawm, lub siab ua rau lub solubility ntawm cov roj hauv cov khoom siv khov kho, ua rau nws ua rau precipitate. Cov npuas yog txo.

Xav tham txog yam uas peb tuaj yeem ua tau rau koj?

Tshawb nrhiav qhov twg peb cov kev daws teeb meem tuaj yeem coj koj.