Khoom

JK15-2401002 Kev Txhawb Nqa Cov Ntaub Ntawv

Khoom Feature

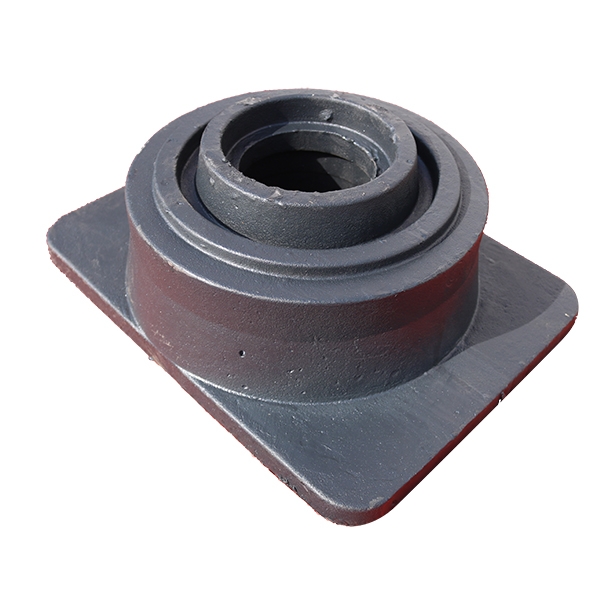

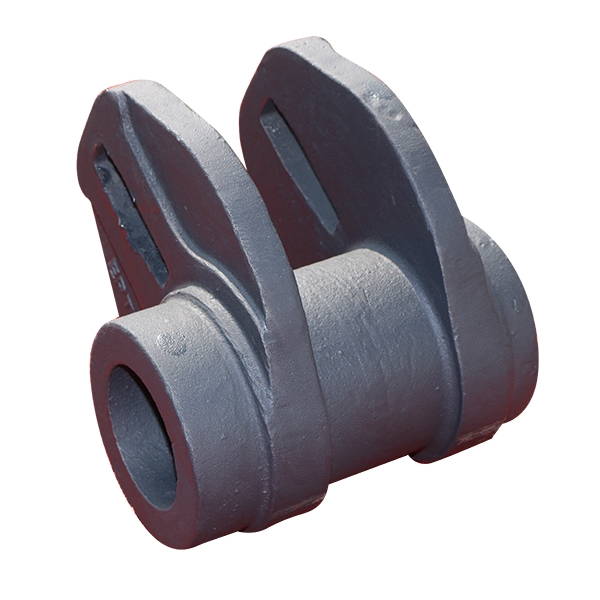

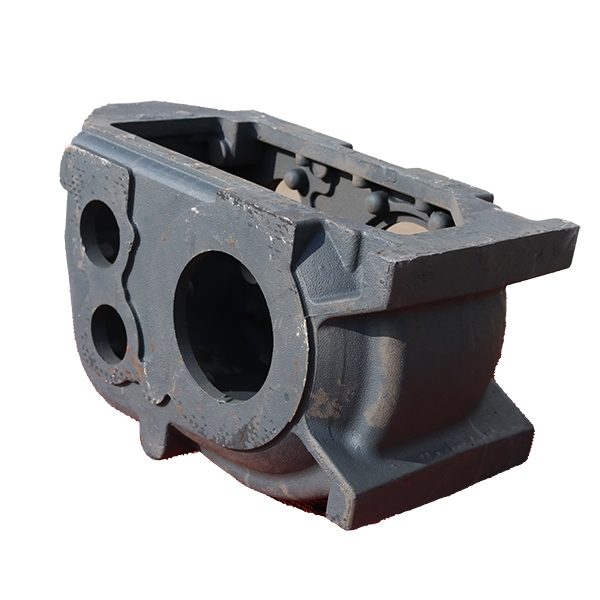

Poob npam casting (tseem hu ua puab yas ua npuas dej rau hauv cov qauv ua npuas ncauj thiab cov kab mob STMMA lossis EPMER) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) polymer) Nrog refractory txheej (muaj zog), du thiab qhuav) thiab qhuav, nws tau faus rau hauv cov xuab zeb qhuav qhuav ua qauv. Lub molten hlau tau nchuav rau hauv cov moulding xuab zeb hauv lub siab tsis zoo, yog li cov qauv polymer yog rhuab thiab muab rho tawm. Ib txoj kev tshiab casting uas siv cov hlau ua kua los hloov ib-zaug pwm ua kom haum cov txheej txheem tom qab txias thiab solidification los tsim cov casings. Poob ua npuas dej casting muaj cov yam ntxwv hauv qab no: 1. Cov khoom siv tau zoo thiab tus nqi qis; 2. Cov ntaub ntawv tsis txwv thiab haum rau txhua qhov ntau thiab tsawg; 3. Lub siab ntsuas, du nto, tsis tu dua, thiab tsawg dua machining; 4. Sab saum toj tsis xws luag yog zoo heev txo thiab cov qauv ntawm cov nrib yog txhim kho. Ntom; 5. Nws tuaj yeem paub cov nplai loj thiab ntau lawm; 6. Nws yog haum rau huab hwm coj ntau lawm Casting ntawm tib cov kab hlau; 7. Nws yog haum rau kev ua haujlwm ntawm kev ua haujlwm thiab cov kab sib dhos ua ke tsim thiab tswj kev ua haujlwm; 8. Cov kab haujlwm ntau lawm ntawm cov kab ntau lawm tau raws li qhov yuav tsum tau muaj kev tiv thaiv ib puag ncig kev tiv thaiv. ; 9. Nws tuaj yeem txhim kho kev ua haujlwm ib puag ncig thiab cov xwm txheej ntau lawm ntawm cov kab ntau lawm, txo kev siv zog ua haujlwm, thiab txo kev siv zog.

Khoom Piav Qhia

Poob npaus casting (raws li xyoo 2018) yog kom tau nyiaj thiab sib xyaw ua ke cov qauv yas zoo sib xyaw nyob rau hauv loj thiab cov duab rau cov kab hlau. Tom qab txhuam hniav nrog cov txheej txheem refractory thiab ziab, lawv tau faus rau hauv cov xuab zeb qhuav qhuav thiab vibrated rau cov duab. Nyob rau hauv qee qhov kev mob ib txoj kev ntawm nchuav cov hlau ua kua, ua rau muaj kev sib txuas thiab ua kom muaj txiaj ntsig thiab txias kom tsim qhov xav tau. Cov txheej txheem tseem ceeb ntawm cov poob ua npuas dej Casting txoj kev yog ntau lawm cov tshuaj ua npuas ncauj thiab cov ntawv thov ntawm refractier pleev roj; Qhov kev co thiab zawm ntawm cov xuab zeb tom qab cov npuas dej tom qab cov tshuab ua npuas ncauj ntoo yas muab tso rau hauv lub thawv xuab zeb; Thiab kev saib xyuas ntawm lub tshuab nqus tsev hauv lub thawv xuab zeb thaum lub sijhawm nchuav. Cov.

Poob npaus casting yog hailed los ntawm lub foundry kev lag luam raws li "kev siv thev naus laus zis tshiab hauv 21st caug xyoo" thiab "A Green Project hauv Casting". Poob npaus casting yog thawj zaug tau sim los ntawm HF shrodman tuam txhab hauv xyoo 1962. Nyob rau hauv thaum ntxov ntxov ntawm daim ntawv thov, ploj ua npuas ncauj ua ke, ploj ua npuas ncauj nplai kab hlau. Txij xyoo 1960s mus rau xyoo 1970, tus mouldetic pwm Casting txoj kev tau tsim. Txij li thaum 1980s, thawj txheej txheem pom los ntawm lub tshuab nqus tsev tsis zoo thiab qhuav xuab zeb tau tsim. Thib 3 tiam poob ua npuas ncauj.

Poob npaus casumte yog cov kev qhia loj uas muaj ntau qhov kev thov uas muaj kev sib xyaw ua ke, tshuaj lom neeg, tshuab thiab kev casting. Nws muab cov txheej txheem ploj ploj nrog lwm cov txheej txheem tshiab ua kom tsim cov txheej txheem tshiab los txhim kho ua npuas ncauj ua npuas dej. thiab ntau lawm kev ua tau zoo ntxiv.

Xav tham txog yam uas peb tuaj yeem ua tau rau koj?

Tshawb nrhiav qhov twg peb cov kev daws teeb meem tuaj yeem coj koj.